[{"CategoryId":271,"CategoryName":"By Series","ParentId":0,"Imageurl":""},{"CategoryId":272,"CategoryName":"By Size","ParentId":0,"Imageurl":""},{"CategoryId":273,"CategoryName":"By Number of Pins","ParentId":0,"Imageurl":""},{"CategoryId":274,"CategoryName":"By Application","ParentId":0,"Imageurl":""},{"CategoryId":275,"CategoryName":"By Wiring","ParentId":0,"Imageurl":""},{"CategoryId":276,"CategoryName":"Customization","ParentId":0,"Imageurl":""},{"CategoryId":277,"CategoryName":"By Material","ParentId":0,"Imageurl":""},{"CategoryId":278,"CategoryName":"LP Series","ParentId":271,"Imageurl":"2025/07/20250724101928371.jpg?TFDns7vliJcuYmlwLjI1NTUuanBn"},{"CategoryId":1319,"CategoryName":"SF Series","ParentId":271,"Imageurl":"2025/09/20250913181601452.jpg?U0Y2LTgtMTDlhajlrrbnpo8uanBn"},{"CategoryId":1245,"CategoryName":"SP Series","ParentId":271,"Imageurl":"2025/09/20250913181428839.jpg?U1AuanBn"},{"CategoryId":279,"CategoryName":"Self Locking Series","ParentId":271,"Imageurl":"2024/09/20240905134920982.png?U2VsZiBMb2NraW5nIFNlcmllcw=="},{"CategoryId":280,"CategoryName":"Waterproof Cable Connector","ParentId":271,"Imageurl":"2024/09/20240905142754587.png?V2F0ZXJwcm9vZiBDYWJsZSBDb25uZWN0b3I="},{"CategoryId":281,"CategoryName":"Junction Box","ParentId":271,"Imageurl":"2024/09/20240905155939966.png?5o6l57q/55uS57O75YiXIDYxM3g2MTMucG5n"},{"CategoryId":1222,"CategoryName":"Cable Gland","ParentId":271,"Imageurl":"2025/03/20250320135315907.jpg?Y2FibGUtZ2xhbmQuanBn"},{"CategoryId":282,"CategoryName":"Energy Storage Connector","ParentId":271,"Imageurl":"2024/09/20240905143234262.png?RW5lcmd5IFN0b3JhZ2UgQ29ubmVjdG9y"},{"CategoryId":1161,"CategoryName":"PV Connector","ParentId":271,"Imageurl":"2024/09/20240905143119031.png?UFYgQ29ubmVjdG9y"},{"CategoryId":1351,"CategoryName":"M29","ParentId":272,"Imageurl":""},{"CategoryId":1170,"CategoryName":"M28","ParentId":272,"Imageurl":"2024/12/20241204113448729.png?TTI4IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1169,"CategoryName":"M25","ParentId":272,"Imageurl":"2024/12/20241204113352959.png?TTI1IGNpcmN1bGFyIHBsYXN0aWMgd2lyZSBjb25uZWN0b3I="},{"CategoryId":319,"CategoryName":"M24","ParentId":272,"Imageurl":"2024/12/20241204113237802.png?TTI0IEluZHVzdHJpYWwgd2F0ZXJwcm9vZiBjb25uZWN0b3I="},{"CategoryId":1168,"CategoryName":"M23","ParentId":272,"Imageurl":"2024/12/20241204112141563.png?TTIzIHdhdGVycHJvb2YgcGx1ZyBjb25uZWN0b3Jz"},{"CategoryId":1350,"CategoryName":"M21","ParentId":272,"Imageurl":""},{"CategoryId":318,"CategoryName":"M20","ParentId":272,"Imageurl":"2024/12/20241204112034702.png?TTIwIGNpcmN1bGFyIGNvbm5lY3Rvcg=="},{"CategoryId":1167,"CategoryName":"M19","ParentId":272,"Imageurl":"2024/12/20241204111937164.png?TTE5IHdhdGVycHJvb2Ygd2lyZSBjb25uZWN0b3Jz"},{"CategoryId":1349,"CategoryName":"M17","ParentId":272,"Imageurl":""},{"CategoryId":293,"CategoryName":"M16","ParentId":272,"Imageurl":"2024/12/20241204111827969.png?TTE2IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1166,"CategoryName":"M15","ParentId":272,"Imageurl":"2024/12/20241204111717740.png?TTE1IG1hbGUgYW5kIGZlbWFsZSBjb25uZWN0b3Jz"},{"CategoryId":1348,"CategoryName":"M13","ParentId":272,"Imageurl":""},{"CategoryId":292,"CategoryName":"M12","ParentId":272,"Imageurl":"2024/12/20241204111548642.png?TTEyIFdhdGVycHJvb2YgTTEyIENvbm5lY3Rvcg=="},{"CategoryId":1347,"CategoryName":"M10","ParentId":272,"Imageurl":""},{"CategoryId":1346,"CategoryName":"M8","ParentId":272,"Imageurl":""},{"CategoryId":1345,"CategoryName":"M6","ParentId":272,"Imageurl":""},{"CategoryId":335,"CategoryName":"TYPE-C","ParentId":273,"Imageurl":"2024/08/20240803175816209.jpg?TFAxNi1UWVBFLUPph5HlsZ7ms5XlhbAuanBn"},{"CategoryId":334,"CategoryName":"Fiber","ParentId":273,"Imageurl":"2024/07/20240730100446602.png?TFAyNC1GSUJFUig2KSAyMDB4MjAwIC0g5Ymv5pysLnBuZw=="},{"CategoryId":333,"CategoryName":"HDMI","ParentId":273,"Imageurl":"2024/07/20240730100616849.png?TFAyNC1IRE1JKDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":332,"CategoryName":"USB","ParentId":273,"Imageurl":"2024/07/20240730100646405.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":331,"CategoryName":"RJ45","ParentId":273,"Imageurl":"2024/07/20240730100713409.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlr7nmjqUucG5n"},{"CategoryId":1335,"CategoryName":"26 Pins","ParentId":273,"Imageurl":"2025/09/20250908170725350.jpg?U1AyOS0yNlDkuKTlrZTluqfmraPoo4UgODAweDgwMC5qcGc="},{"CategoryId":330,"CategoryName":"24 Pins","ParentId":273,"Imageurl":"2024/07/20240730101220115.jpg?TFAyNC0yNFDpnaLmnb/ph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1334,"CategoryName":"20 Pins","ParentId":273,"Imageurl":"2025/09/20250908170702461.jpg?U0YyOC0yMFDpnaLmnb8gODAweDgwMC5qcGc="},{"CategoryId":329,"CategoryName":"19 Pins","ParentId":273,"Imageurl":"2024/07/20240730101243254.jpg?TFAyNC0xOVDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1333,"CategoryName":"18 Pins","ParentId":273,"Imageurl":"2025/09/20250908170641433.jpg?U0YyOC0xOFDlr7nmjqUgODAweDgwMC5qcGc="},{"CategoryId":1344,"CategoryName":"17 Pins","ParentId":273,"Imageurl":""},{"CategoryId":1332,"CategoryName":"16 Pins","ParentId":273,"Imageurl":"2025/09/20250908170620266.jpg?U0YyOC0xNlDpnaLmnb/luqflj43oo4UgODAweDgwMC5qcGc="},{"CategoryId":1215,"CategoryName":"14 Pins","ParentId":273,"Imageurl":"2024/08/20240808120100973.jpg?TFAyMC0xNFDms5XlhbDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":328,"CategoryName":"12 Pins","ParentId":273,"Imageurl":"2024/07/20240730101400996.png?TFAyNC0xMlDms5XlhbDloZHmlpnlj43oo4XmrL4ucG5n"},{"CategoryId":327,"CategoryName":"10 Pins","ParentId":273,"Imageurl":"2024/07/20240730101422023.jpg?TFAyNC0xMFDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":326,"CategoryName":"9 Pins","ParentId":273,"Imageurl":"2024/07/20240730101545901.jpg?TFAyMC05UC3lr7nmj5ItMy5qcGc="},{"CategoryId":325,"CategoryName":"8 Pins","ParentId":273,"Imageurl":"2024/07/20240730101729864.jpg?TFAxNi04UOmdouadv0zph5HlsZ7mraPoo4UuanBn"},{"CategoryId":324,"CategoryName":"7 Pins","ParentId":273,"Imageurl":"2024/07/20240730101805407.jpg?TFAxNi03UOazleWFsFDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":323,"CategoryName":"6 Pins","ParentId":273,"Imageurl":"2024/07/20240730101848277.png?TFAxMi02UCDlj43oo4UgMi5wbmc="},{"CategoryId":322,"CategoryName":"5 Pins","ParentId":273,"Imageurl":"2024/07/20240730102001465.jpg?TFAyNC01UOWFrOaPklPph5HlsZ7lj43oo4XplIHnur/mrL4uanBn"},{"CategoryId":321,"CategoryName":"4 Pins","ParentId":273,"Imageurl":"2024/07/20240730102053511.png?TFAyMC00UOazleWFsOWhkeaWmeato+ijhS5wbmc="},{"CategoryId":320,"CategoryName":"3 Pins","ParentId":273,"Imageurl":"2024/07/20240730102122414.jpg?TFAyOC0zUOWvueaPkuWhkeaWmeato+ijhS5qcGc="},{"CategoryId":295,"CategoryName":"2 Pins","ParentId":273,"Imageurl":"2024/07/20240730102152158.jpg?TFAyOC0yUOazleWFsOWhkeaWmeato+ijhS5qcGc="},{"CategoryId":294,"CategoryName":"1 Pin","ParentId":273,"Imageurl":"2024/12/20241202141836844.png?ZW5lcmd5IHN0b3JhZ2UgY29ubmVjdG9y"},{"CategoryId":315,"CategoryName":"Signal Connector","ParentId":274,"Imageurl":"2024/07/20240730133750759.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":297,"CategoryName":"Data Connector","ParentId":274,"Imageurl":"2024/07/20240730093457270.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":296,"CategoryName":"Power Connector","ParentId":274,"Imageurl":"2024/08/20240803175721975.jpg?TFAxNi00UCg5KS5qcGc="},{"CategoryId":338,"CategoryName":"Crimping Type","ParentId":275,"Imageurl":"2024/12/20241202143025954.png?TFAxMi0yUOWvueaPkumHkeWxnuato+ijhSA3NTB4NzUwLnBuZw=="},{"CategoryId":336,"CategoryName":"Solder Type","ParentId":275,"Imageurl":"2024/12/20241202142826795.png?TFAyNC0y6Iqv54SK5o6l5aGR5paZ5qy+5rOV5YWw5Y+N6KOFc2t1LnBuZw=="},{"CategoryId":337,"CategoryName":"Screw Type","ParentId":275,"Imageurl":"2024/12/20241202142506193.png?TFAxMi0yUOazleWFsFDph5HlsZ7plIHnur/lj43oo4UucG5n"},{"CategoryId":298,"CategoryName":"Screwless Type","ParentId":275,"Imageurl":"2024/05/20240529162027688.jpg?5b+r5o6l57O75YiXLmpwZw=="},{"CategoryId":301,"CategoryName":"Mix Pins","ParentId":276,"Imageurl":"2024/07/20240730102324120.jpg?TFAyOC0zUOazleWFsOWhkeaWmeato+ijhS0xLmpwZw=="},{"CategoryId":1330,"CategoryName":"Color","ParentId":276,"Imageurl":""},{"CategoryId":317,"CategoryName":"Metal + Plastic","ParentId":277,"Imageurl":"2024/08/20240803180032739.jpg?TFAxMi00UOazleWFsOmHkeWxnuWPjeijhS5qcGc="},{"CategoryId":316,"CategoryName":"All Metal","ParentId":277,"Imageurl":"2024/11/20241121135153910.png?TFAxMi0yUOazleWFsOasvumUgee6vy5wbmc="},{"CategoryId":300,"CategoryName":"All Plastic","ParentId":277,"Imageurl":"2024/08/20240803180224853.png?TFAxMi00UCDlj43oo4UgNy5wbmc="},{"CategoryId":287,"CategoryName":"LP12","ParentId":278,"Imageurl":"2024/12/20241203141919861.png?TFAxMiBlbGVjdHJpY2FsIHdhdGVycHJvb2YgY29ubmVjdG9ycw=="},{"CategoryId":283,"CategoryName":"LP16","ParentId":278,"Imageurl":"2024/12/20241203141926793.png?TFAxNiB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":286,"CategoryName":"LP20","ParentId":278,"Imageurl":"2024/12/20241203140522654.png?TFAyMCBJbmR1c3RyaWFsIHdhdGVycHJvb2YgY29ubmVjdG9y"},{"CategoryId":285,"CategoryName":"LP24","ParentId":278,"Imageurl":"2024/12/20241203140638274.jpg?TFAyNCB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":284,"CategoryName":"LP28","ParentId":278,"Imageurl":"2024/12/20241203140831377.png?TFAyOCBXYXRlcnByb29mIENhYmxlIENvbm5lY3Rvcg=="},{"CategoryId":303,"CategoryName":"M15MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095659595.jpg?TTE1TUYtM1AuanBn"},{"CategoryId":304,"CategoryName":"M19MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095626837.jpg?6Z2i5p2/55m95bqVIC0g5Ymv5pysLmpwZw=="},{"CategoryId":305,"CategoryName":"M23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095548936.jpg?RVctTTIzTVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":307,"CategoryName":"M28MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095408770.jpg?RVctTTI4TVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":306,"CategoryName":"P25MP/MF","ParentId":279,"Imageurl":"2024/07/20240729185729105.png?UDI1LS3oiq/mlbAt5aSW57q/55u05b6E5Zu+IDIwMHgyMDAucG5n"},{"CategoryId":1209,"CategoryName":"P23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730100244127.png?UDIzLnBuZw=="},{"CategoryId":302,"CategoryName":"Screw Connector Series","ParentId":280,"Imageurl":"2024/12/20241203142740551.png?U2NyZXcgQ29ubmVjdG9yIFNlcmllcw=="},{"CategoryId":289,"CategoryName":"Screwless Connector Series","ParentId":280,"Imageurl":"2024/09/20240905144436844.png?U2NyZXdsZXNzIENvbm5lY3RvciBTZXJpZXM="},{"CategoryId":290,"CategoryName":"2068 Serie","ParentId":281,"Imageurl":"2024/07/20240730094848584.png?RVctTTIwNjgtNVQucG5n"},{"CategoryId":1536,"CategoryName":"2068N Serie","ParentId":281,"Imageurl":"2026/01/20260116110540406.png?TTIwNjhOLTJUICAoMikucG5n"},{"CategoryId":1538,"CategoryName":"2068R Serie","ParentId":281,"Imageurl":"2026/02/20260206151256783.png?RVctTTIwNjhSLTFUICgxKS5wbmc="},{"CategoryId":308,"CategoryName":"2068S Serie","ParentId":281,"Imageurl":"2024/07/20240729190104148.jpg?55m95bqVMy5qcGc="},{"CategoryId":309,"CategoryName":"2068L Serie","ParentId":281,"Imageurl":"2024/07/20240729190043564.jpg?55m95bqVMi5qcGc="},{"CategoryId":310,"CategoryName":"2068XL Serie","ParentId":281,"Imageurl":"2024/07/20240730094724530.jpg?MTAuanBn"},{"CategoryId":1159,"CategoryName":"350A","ParentId":282,"Imageurl":"2024/07/20240729190329212.jpg?RTMwMC0zNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":1158,"CategoryName":"300A","ParentId":282,"Imageurl":"2024/07/20240729190349998.jpg?RTMwMOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":341,"CategoryName":"250A","ParentId":282,"Imageurl":"2024/07/20240729190408955.jpg?RTEwMC0yNTDlj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":340,"CategoryName":"200A","ParentId":282,"Imageurl":"2024/07/20240729190435882.jpg?RTI1MOS4jeWPr+aXi+i9rOieuuafsem7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":339,"CategoryName":"150A","ParentId":282,"Imageurl":"2024/07/20240729190456384.jpg?RTEwMC0yNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":311,"CategoryName":"120A","ParentId":282,"Imageurl":"2024/07/20240729190538607.jpg?RTI1MOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":312,"CategoryName":"100A","ParentId":282,"Imageurl":"2024/07/20240729190551775.jpg?RTEwMC0yNTDkuI3lj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":313,"CategoryName":"70A","ParentId":282,"Imageurl":"2024/07/20240729190619040.jpg?RTUw5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S6buR6Imy5aWX6KOFU0tVXy5qcGc="},{"CategoryId":314,"CategoryName":"50A","ParentId":282,"Imageurl":"2024/07/20240729190633170.jpg?RTUwLTcw5LiN5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S5qmZ6Imy5aWX6KOFU0tVLmpwZw=="},{"CategoryId":1533,"CategoryName":"LP20","ParentId":298,"Imageurl":""},{"CategoryId":1526,"CategoryName":"M25B","ParentId":298,"Imageurl":""},{"CategoryId":299,"CategoryName":"P25","ParentId":298,"Imageurl":"2024/05/20240529162134233.jpg?UDIzLjIuanBn"},{"CategoryId":1531,"CategoryName":"P23","ParentId":298,"Imageurl":""},{"CategoryId":1107,"CategoryName":"P20","ParentId":298,"Imageurl":"2024/09/20240909134224415.png?UDIwLS3oiq/mlbAt5aSW57q/55u05b6E5Zu+LSA2MTN4NjEzLnBuZw=="},{"CategoryId":1530,"CategoryName":"P25X","ParentId":298,"Imageurl":""},{"CategoryId":1529,"CategoryName":"P25T","ParentId":298,"Imageurl":""},{"CategoryId":1528,"CategoryName":"P20X","ParentId":298,"Imageurl":""},{"CategoryId":1527,"CategoryName":"P20T","ParentId":298,"Imageurl":""},{"CategoryId":1165,"CategoryName":"65A","ParentId":1161,"Imageurl":"2024/07/20240729190717746.jpg?MTBtbcKy6Z2i5p2/5bel5YW36Kej6ZSB5YWs5o+S5aS0LmpwZw=="},{"CategoryId":1164,"CategoryName":"45A","ParentId":1161,"Imageurl":"2024/07/20240729190731167.jpg?Nm1twrLnur/nq6/lt6Xop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1163,"CategoryName":"35A","ParentId":1161,"Imageurl":"2024/07/20240729190743086.jpg?NG1twrLnur/nq6/lt6Xlhbfop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1201,"CategoryName":"25A","ParentId":1161,"Imageurl":"2024/07/20240729190756464.jpg?Mi41bW3Csue6v+err+W3peWFt+ino+mUgeWFrOaPkuWktC5qcGc="},{"CategoryId":1223,"CategoryName":"PG Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1243,"CategoryName":"PG Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1224,"CategoryName":"M Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1244,"CategoryName":"M Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1247,"CategoryName":"SP13","ParentId":1245,"Imageurl":""},{"CategoryId":1246,"CategoryName":"SP17","ParentId":1245,"Imageurl":""},{"CategoryId":1327,"CategoryName":"SP21","ParentId":1245,"Imageurl":""},{"CategoryId":1326,"CategoryName":"SP29","ParentId":1245,"Imageurl":""},{"CategoryId":1320,"CategoryName":"SF6","ParentId":1319,"Imageurl":""},{"CategoryId":1321,"CategoryName":"SF8","ParentId":1319,"Imageurl":""},{"CategoryId":1328,"CategoryName":"SF10","ParentId":1319,"Imageurl":""},{"CategoryId":1322,"CategoryName":"SF12","ParentId":1319,"Imageurl":""},{"CategoryId":1323,"CategoryName":"SF16","ParentId":1319,"Imageurl":""},{"CategoryId":1324,"CategoryName":"SF20","ParentId":1319,"Imageurl":""},{"CategoryId":1325,"CategoryName":"SF28","ParentId":1319,"Imageurl":""}]

Waterproof Connectors Are Designed To Protect Electrical Connections From Moisture-Industrial Control Equipment

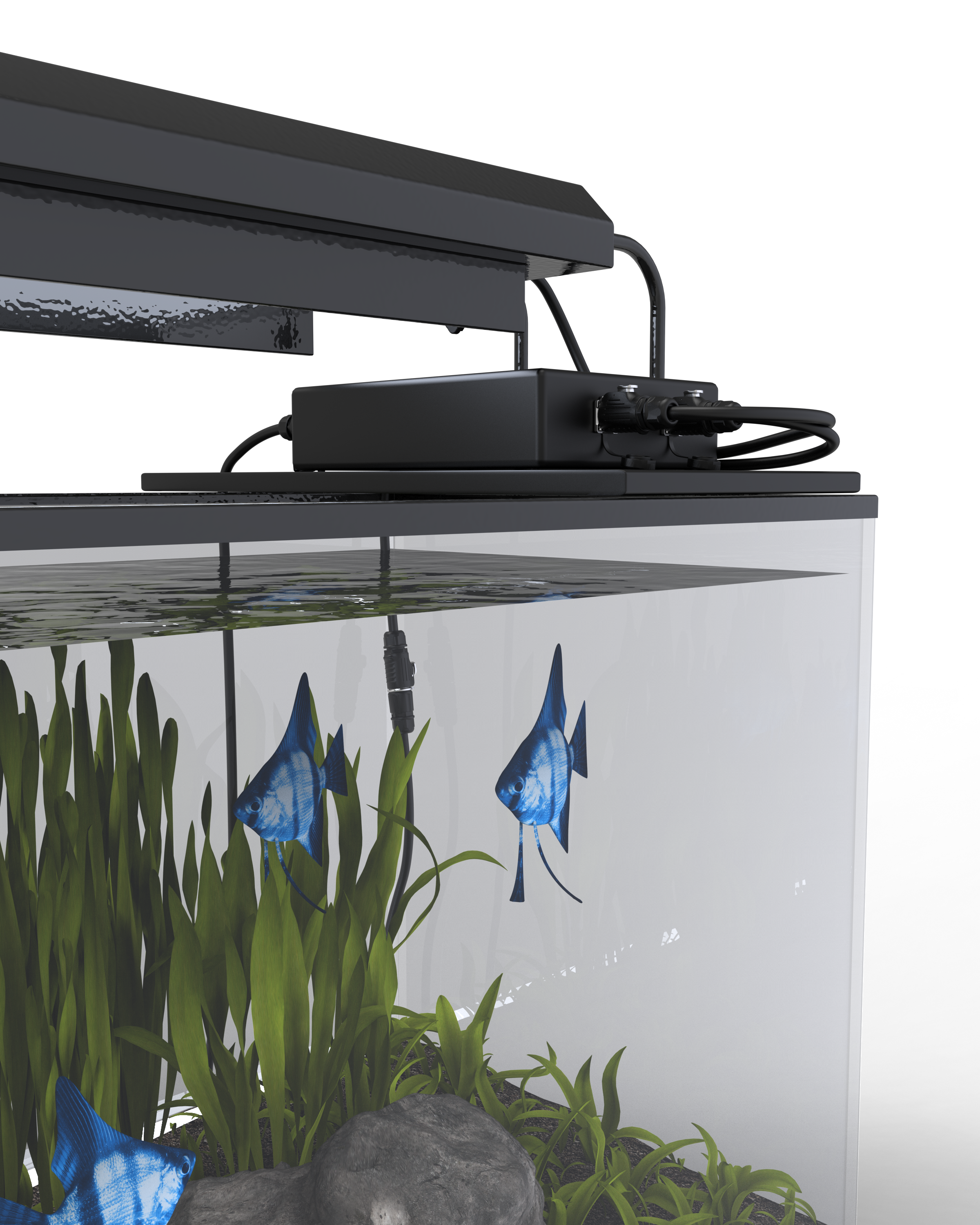

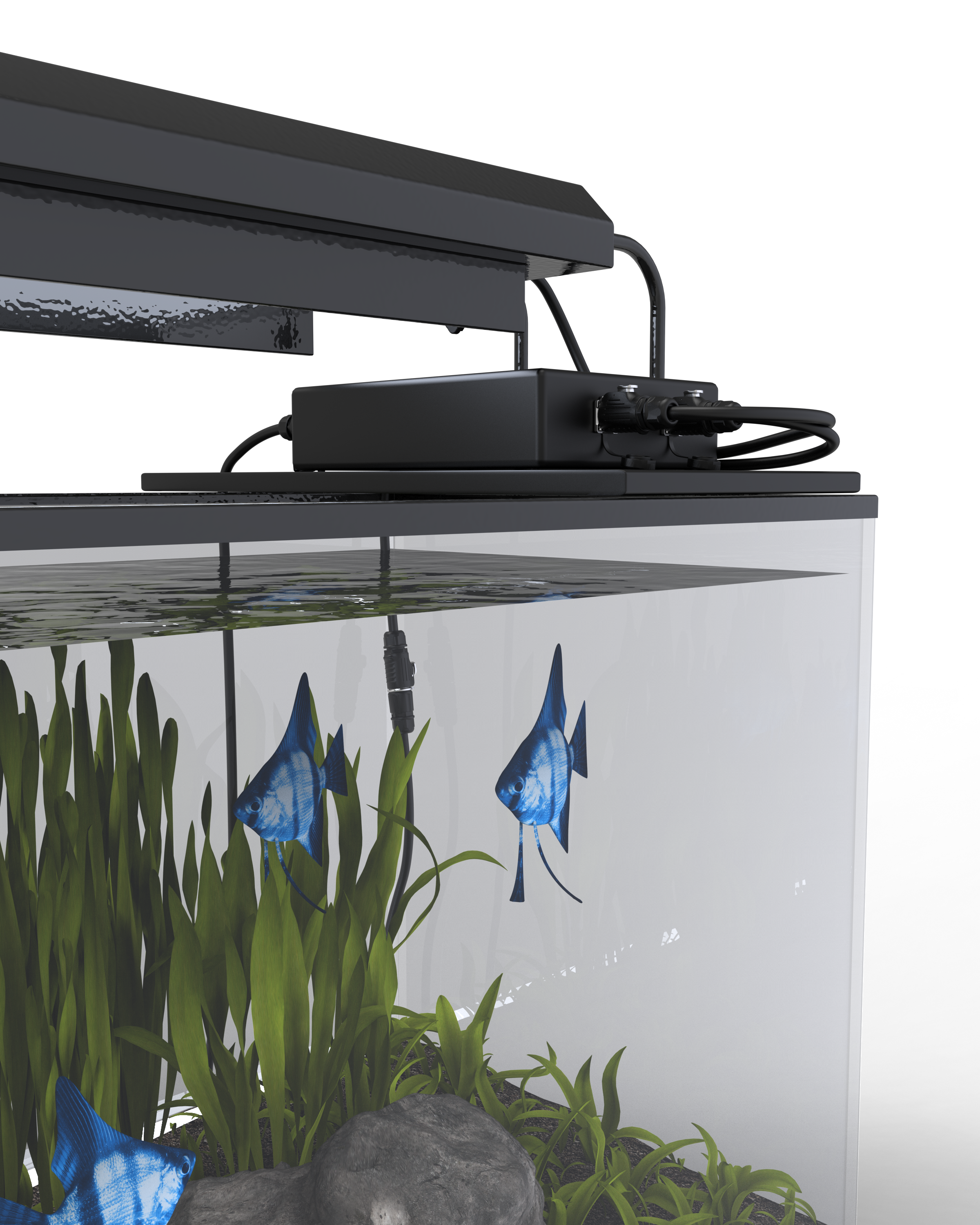

In today's industrial landscape, the reliability and efficiency of control systems are paramount, and one critical component that significantly contributes to these factors is the waterproof connector. Waterproof connectors are designed to protect electrical connections from moisture, dust, and other environmental contaminants, ensuring optimal performance in harsh conditions. As industries increasingly demand robust solutions capable of withstanding extreme environments, the importance of waterproof connectors has grown tremendously.

By providing secure and reliable connections, waterproof connectors help prevent system failures, reduce downtime, and enhance overall operational safety. This introduction sets the stage for an in-depth exploration of waterproof connectors, including their types, materials, sealing technologies, and applications, as well as the benefits they offer and the challenges associated with their use in industrial control equipment. Understanding these aspects is crucial for businesses aiming to leverage the advantages of waterproof connectors in their operations.

Applications of Waterproof Connectors in Industrial Control Equipment

In manufacturing and automation, these connectors safeguard equipment from moisture and dust, enhancing operational efficiency and minimizing downtime. In the oil and gas industry, waterproof connectors are essential for equipment deployed in harsh conditions, providing reliable performance in offshore drilling and exploration, where exposure to water and corrosive elements is prevalent.

Marine and offshore applications also significantly benefit from waterproof connectors, as they are designed to withstand the rigors of saltwater exposure, ensuring the integrity of communication and power systems aboard ships and offshore platforms. Additionally, in the food and beverage industry, waterproof connectors are vital for maintaining hygiene and ensuring compliance with safety standards, as they prevent contamination and facilitate easy cleaning of equipment.

Benefits of Using Waterproof Connectors

Enhanced Reliability: One of the primary benefits is their ability to maintain a reliable connection in harsh environments. These connectors are designed to withstand exposure to moisture, dust, and other contaminants, reducing the risk of connection failures and ensuring the continuous operation of industrial equipment.

Improved Safety: Waterproof connectors contribute to enhanced safety in industrial settings. By preventing water ingress and electrical short circuits, these connectors mitigate the risk of accidents and equipment malfunctions, protecting both personnel and machinery.

Cost Efficiency: While the initial investment may be higher, waterproof connectors can lead to long-term cost savings. Their durability reduces maintenance needs and downtime, translating to lower operational costs over time. Additionally, the extended lifespan of waterproof connectors means less frequent replacements, further enhancing cost efficiency.

Challenges and Considerations

1. Environmental Factors: Industrial environments often expose connectors to extreme conditions, including temperature fluctuations, humidity, dust, and corrosive substances. Selecting connectors that can withstand these harsh conditions is crucial to ensure longevity and performance.

2. Installation and Maintenance: Proper installation is critical for maintaining the integrity of waterproof connectors. Misalignment or improper sealing can lead to failure. Additionally, maintenance procedures must be developed to ensure that connectors remain functional over time, which may require regular inspections and servicing.

3.Selection Criteria: Choosing the right waterproof connector involves careful consideration of various factors, including the specific environmental conditions, electrical requirements, and compatibility with existing systems. It's essential to evaluate the materials, sealing methods, and configurations to ensure optimal performance and reliability in the intended application.

As industries continue to evolve, the demand for advanced waterproof connector technologies is on the rise. New materials, such as advanced polymers and composites, offer enhanced durability, resistance to harsh chemicals, and improved thermal stability, making connectors more reliable in extreme environments.

With the advent of the Internet of Things (IoT), connectors are now being designed with embedded sensors and communication capabilities that allow for real-time monitoring and diagnostics. This not only improves operational efficiency but also enables predictive maintenance, reducing downtime and costs. This includes using recyclable materials and reducing waste throughout the production process.

-

Fast and Convenient

-

Customization

- Need a technical consultant to answer your questions?

-

-

Hot Promoted Products

Recommend current hot products to you