[{"CategoryId":271,"CategoryName":"By Series","ParentId":0,"Imageurl":""},{"CategoryId":272,"CategoryName":"By Size","ParentId":0,"Imageurl":""},{"CategoryId":273,"CategoryName":"By Number of Pins","ParentId":0,"Imageurl":""},{"CategoryId":274,"CategoryName":"By Application","ParentId":0,"Imageurl":""},{"CategoryId":275,"CategoryName":"By Wiring","ParentId":0,"Imageurl":""},{"CategoryId":276,"CategoryName":"Customization","ParentId":0,"Imageurl":""},{"CategoryId":277,"CategoryName":"By Material","ParentId":0,"Imageurl":""},{"CategoryId":278,"CategoryName":"LP Series","ParentId":271,"Imageurl":"2025/07/20250724101928371.jpg?TFDns7vliJcuYmlwLjI1NTUuanBn"},{"CategoryId":1319,"CategoryName":"SF Series","ParentId":271,"Imageurl":"2025/09/20250913181601452.jpg?U0Y2LTgtMTDlhajlrrbnpo8uanBn"},{"CategoryId":1245,"CategoryName":"SP Series","ParentId":271,"Imageurl":"2025/09/20250913181428839.jpg?U1AuanBn"},{"CategoryId":279,"CategoryName":"Self Locking Series","ParentId":271,"Imageurl":"2024/09/20240905134920982.png?U2VsZiBMb2NraW5nIFNlcmllcw=="},{"CategoryId":280,"CategoryName":"Waterproof Cable Connector","ParentId":271,"Imageurl":"2024/09/20240905142754587.png?V2F0ZXJwcm9vZiBDYWJsZSBDb25uZWN0b3I="},{"CategoryId":281,"CategoryName":"Junction Box","ParentId":271,"Imageurl":"2024/09/20240905155939966.png?5o6l57q/55uS57O75YiXIDYxM3g2MTMucG5n"},{"CategoryId":1222,"CategoryName":"Cable Gland","ParentId":271,"Imageurl":"2025/03/20250320135315907.jpg?Y2FibGUtZ2xhbmQuanBn"},{"CategoryId":282,"CategoryName":"Energy Storage Connector","ParentId":271,"Imageurl":"2024/09/20240905143234262.png?RW5lcmd5IFN0b3JhZ2UgQ29ubmVjdG9y"},{"CategoryId":1161,"CategoryName":"PV Connector","ParentId":271,"Imageurl":"2024/09/20240905143119031.png?UFYgQ29ubmVjdG9y"},{"CategoryId":1351,"CategoryName":"M29","ParentId":272,"Imageurl":""},{"CategoryId":1170,"CategoryName":"M28","ParentId":272,"Imageurl":"2024/12/20241204113448729.png?TTI4IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1169,"CategoryName":"M25","ParentId":272,"Imageurl":"2024/12/20241204113352959.png?TTI1IGNpcmN1bGFyIHBsYXN0aWMgd2lyZSBjb25uZWN0b3I="},{"CategoryId":319,"CategoryName":"M24","ParentId":272,"Imageurl":"2024/12/20241204113237802.png?TTI0IEluZHVzdHJpYWwgd2F0ZXJwcm9vZiBjb25uZWN0b3I="},{"CategoryId":1168,"CategoryName":"M23","ParentId":272,"Imageurl":"2024/12/20241204112141563.png?TTIzIHdhdGVycHJvb2YgcGx1ZyBjb25uZWN0b3Jz"},{"CategoryId":1350,"CategoryName":"M21","ParentId":272,"Imageurl":""},{"CategoryId":318,"CategoryName":"M20","ParentId":272,"Imageurl":"2024/12/20241204112034702.png?TTIwIGNpcmN1bGFyIGNvbm5lY3Rvcg=="},{"CategoryId":1167,"CategoryName":"M19","ParentId":272,"Imageurl":"2024/12/20241204111937164.png?TTE5IHdhdGVycHJvb2Ygd2lyZSBjb25uZWN0b3Jz"},{"CategoryId":1349,"CategoryName":"M17","ParentId":272,"Imageurl":""},{"CategoryId":293,"CategoryName":"M16","ParentId":272,"Imageurl":"2024/12/20241204111827969.png?TTE2IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1166,"CategoryName":"M15","ParentId":272,"Imageurl":"2024/12/20241204111717740.png?TTE1IG1hbGUgYW5kIGZlbWFsZSBjb25uZWN0b3Jz"},{"CategoryId":1348,"CategoryName":"M13","ParentId":272,"Imageurl":""},{"CategoryId":292,"CategoryName":"M12","ParentId":272,"Imageurl":"2024/12/20241204111548642.png?TTEyIFdhdGVycHJvb2YgTTEyIENvbm5lY3Rvcg=="},{"CategoryId":1347,"CategoryName":"M10","ParentId":272,"Imageurl":""},{"CategoryId":1346,"CategoryName":"M8","ParentId":272,"Imageurl":""},{"CategoryId":1345,"CategoryName":"M6","ParentId":272,"Imageurl":""},{"CategoryId":335,"CategoryName":"TYPE-C","ParentId":273,"Imageurl":"2024/08/20240803175816209.jpg?TFAxNi1UWVBFLUPph5HlsZ7ms5XlhbAuanBn"},{"CategoryId":334,"CategoryName":"Fiber","ParentId":273,"Imageurl":"2024/07/20240730100446602.png?TFAyNC1GSUJFUig2KSAyMDB4MjAwIC0g5Ymv5pysLnBuZw=="},{"CategoryId":333,"CategoryName":"HDMI","ParentId":273,"Imageurl":"2024/07/20240730100616849.png?TFAyNC1IRE1JKDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":332,"CategoryName":"USB","ParentId":273,"Imageurl":"2024/07/20240730100646405.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":331,"CategoryName":"RJ45","ParentId":273,"Imageurl":"2024/07/20240730100713409.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlr7nmjqUucG5n"},{"CategoryId":1335,"CategoryName":"26 Pins","ParentId":273,"Imageurl":"2025/09/20250908170725350.jpg?U1AyOS0yNlDkuKTlrZTluqfmraPoo4UgODAweDgwMC5qcGc="},{"CategoryId":330,"CategoryName":"24 Pins","ParentId":273,"Imageurl":"2024/07/20240730101220115.jpg?TFAyNC0yNFDpnaLmnb/ph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1334,"CategoryName":"20 Pins","ParentId":273,"Imageurl":"2025/09/20250908170702461.jpg?U0YyOC0yMFDpnaLmnb8gODAweDgwMC5qcGc="},{"CategoryId":329,"CategoryName":"19 Pins","ParentId":273,"Imageurl":"2024/07/20240730101243254.jpg?TFAyNC0xOVDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1333,"CategoryName":"18 Pins","ParentId":273,"Imageurl":"2025/09/20250908170641433.jpg?U0YyOC0xOFDlr7nmjqUgODAweDgwMC5qcGc="},{"CategoryId":1344,"CategoryName":"17 Pins","ParentId":273,"Imageurl":""},{"CategoryId":1332,"CategoryName":"16 Pins","ParentId":273,"Imageurl":"2025/09/20250908170620266.jpg?U0YyOC0xNlDpnaLmnb/luqflj43oo4UgODAweDgwMC5qcGc="},{"CategoryId":1215,"CategoryName":"14 Pins","ParentId":273,"Imageurl":"2024/08/20240808120100973.jpg?TFAyMC0xNFDms5XlhbDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":328,"CategoryName":"12 Pins","ParentId":273,"Imageurl":"2024/07/20240730101400996.png?TFAyNC0xMlDms5XlhbDloZHmlpnlj43oo4XmrL4ucG5n"},{"CategoryId":327,"CategoryName":"10 Pins","ParentId":273,"Imageurl":"2024/07/20240730101422023.jpg?TFAyNC0xMFDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":326,"CategoryName":"9 Pins","ParentId":273,"Imageurl":"2024/07/20240730101545901.jpg?TFAyMC05UC3lr7nmj5ItMy5qcGc="},{"CategoryId":325,"CategoryName":"8 Pins","ParentId":273,"Imageurl":"2024/07/20240730101729864.jpg?TFAxNi04UOmdouadv0zph5HlsZ7mraPoo4UuanBn"},{"CategoryId":324,"CategoryName":"7 Pins","ParentId":273,"Imageurl":"2024/07/20240730101805407.jpg?TFAxNi03UOazleWFsFDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":323,"CategoryName":"6 Pins","ParentId":273,"Imageurl":"2024/07/20240730101848277.png?TFAxMi02UCDlj43oo4UgMi5wbmc="},{"CategoryId":322,"CategoryName":"5 Pins","ParentId":273,"Imageurl":"2024/07/20240730102001465.jpg?TFAyNC01UOWFrOaPklPph5HlsZ7lj43oo4XplIHnur/mrL4uanBn"},{"CategoryId":321,"CategoryName":"4 Pins","ParentId":273,"Imageurl":"2024/07/20240730102053511.png?TFAyMC00UOazleWFsOWhkeaWmeato+ijhS5wbmc="},{"CategoryId":320,"CategoryName":"3 Pins","ParentId":273,"Imageurl":"2024/07/20240730102122414.jpg?TFAyOC0zUOWvueaPkuWhkeaWmeato+ijhS5qcGc="},{"CategoryId":295,"CategoryName":"2 Pins","ParentId":273,"Imageurl":"2024/07/20240730102152158.jpg?TFAyOC0yUOazleWFsOWhkeaWmeato+ijhS5qcGc="},{"CategoryId":294,"CategoryName":"1 Pin","ParentId":273,"Imageurl":"2024/12/20241202141836844.png?ZW5lcmd5IHN0b3JhZ2UgY29ubmVjdG9y"},{"CategoryId":315,"CategoryName":"Signal Connector","ParentId":274,"Imageurl":"2024/07/20240730133750759.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":297,"CategoryName":"Data Connector","ParentId":274,"Imageurl":"2024/07/20240730093457270.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":296,"CategoryName":"Power Connector","ParentId":274,"Imageurl":"2024/08/20240803175721975.jpg?TFAxNi00UCg5KS5qcGc="},{"CategoryId":338,"CategoryName":"Crimping Type","ParentId":275,"Imageurl":"2024/12/20241202143025954.png?TFAxMi0yUOWvueaPkumHkeWxnuato+ijhSA3NTB4NzUwLnBuZw=="},{"CategoryId":336,"CategoryName":"Solder Type","ParentId":275,"Imageurl":"2024/12/20241202142826795.png?TFAyNC0y6Iqv54SK5o6l5aGR5paZ5qy+5rOV5YWw5Y+N6KOFc2t1LnBuZw=="},{"CategoryId":337,"CategoryName":"Screw Type","ParentId":275,"Imageurl":"2024/12/20241202142506193.png?TFAxMi0yUOazleWFsFDph5HlsZ7plIHnur/lj43oo4UucG5n"},{"CategoryId":298,"CategoryName":"Screwless Type","ParentId":275,"Imageurl":"2024/05/20240529162027688.jpg?5b+r5o6l57O75YiXLmpwZw=="},{"CategoryId":301,"CategoryName":"Mix Pins","ParentId":276,"Imageurl":"2024/07/20240730102324120.jpg?TFAyOC0zUOazleWFsOWhkeaWmeato+ijhS0xLmpwZw=="},{"CategoryId":1330,"CategoryName":"Color","ParentId":276,"Imageurl":""},{"CategoryId":317,"CategoryName":"Metal + Plastic","ParentId":277,"Imageurl":"2024/08/20240803180032739.jpg?TFAxMi00UOazleWFsOmHkeWxnuWPjeijhS5qcGc="},{"CategoryId":316,"CategoryName":"All Metal","ParentId":277,"Imageurl":"2024/11/20241121135153910.png?TFAxMi0yUOazleWFsOasvumUgee6vy5wbmc="},{"CategoryId":300,"CategoryName":"All Plastic","ParentId":277,"Imageurl":"2024/08/20240803180224853.png?TFAxMi00UCDlj43oo4UgNy5wbmc="},{"CategoryId":287,"CategoryName":"LP12","ParentId":278,"Imageurl":"2024/12/20241203141919861.png?TFAxMiBlbGVjdHJpY2FsIHdhdGVycHJvb2YgY29ubmVjdG9ycw=="},{"CategoryId":283,"CategoryName":"LP16","ParentId":278,"Imageurl":"2024/12/20241203141926793.png?TFAxNiB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":286,"CategoryName":"LP20","ParentId":278,"Imageurl":"2024/12/20241203140522654.png?TFAyMCBJbmR1c3RyaWFsIHdhdGVycHJvb2YgY29ubmVjdG9y"},{"CategoryId":285,"CategoryName":"LP24","ParentId":278,"Imageurl":"2024/12/20241203140638274.jpg?TFAyNCB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":284,"CategoryName":"LP28","ParentId":278,"Imageurl":"2024/12/20241203140831377.png?TFAyOCBXYXRlcnByb29mIENhYmxlIENvbm5lY3Rvcg=="},{"CategoryId":303,"CategoryName":"M15MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095659595.jpg?TTE1TUYtM1AuanBn"},{"CategoryId":304,"CategoryName":"M19MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095626837.jpg?6Z2i5p2/55m95bqVIC0g5Ymv5pysLmpwZw=="},{"CategoryId":305,"CategoryName":"M23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095548936.jpg?RVctTTIzTVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":307,"CategoryName":"M28MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095408770.jpg?RVctTTI4TVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":306,"CategoryName":"P25MP/MF","ParentId":279,"Imageurl":"2024/07/20240729185729105.png?UDI1LS3oiq/mlbAt5aSW57q/55u05b6E5Zu+IDIwMHgyMDAucG5n"},{"CategoryId":1209,"CategoryName":"P23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730100244127.png?UDIzLnBuZw=="},{"CategoryId":302,"CategoryName":"Screw Connector Series","ParentId":280,"Imageurl":"2024/12/20241203142740551.png?U2NyZXcgQ29ubmVjdG9yIFNlcmllcw=="},{"CategoryId":289,"CategoryName":"Screwless Connector Series","ParentId":280,"Imageurl":"2024/09/20240905144436844.png?U2NyZXdsZXNzIENvbm5lY3RvciBTZXJpZXM="},{"CategoryId":1536,"CategoryName":"2068N Serie","ParentId":281,"Imageurl":"2026/01/20260116110540406.png?TTIwNjhOLTJUICAoMikucG5n"},{"CategoryId":290,"CategoryName":"2068 Serie","ParentId":281,"Imageurl":"2024/07/20240730094848584.png?RVctTTIwNjgtNVQucG5n"},{"CategoryId":308,"CategoryName":"2068S Serie","ParentId":281,"Imageurl":"2024/07/20240729190104148.jpg?55m95bqVMy5qcGc="},{"CategoryId":309,"CategoryName":"2068L Serie","ParentId":281,"Imageurl":"2024/07/20240729190043564.jpg?55m95bqVMi5qcGc="},{"CategoryId":310,"CategoryName":"2068XL Serie","ParentId":281,"Imageurl":"2024/07/20240730094724530.jpg?MTAuanBn"},{"CategoryId":1159,"CategoryName":"350A","ParentId":282,"Imageurl":"2024/07/20240729190329212.jpg?RTMwMC0zNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":1158,"CategoryName":"300A","ParentId":282,"Imageurl":"2024/07/20240729190349998.jpg?RTMwMOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":341,"CategoryName":"250A","ParentId":282,"Imageurl":"2024/07/20240729190408955.jpg?RTEwMC0yNTDlj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":340,"CategoryName":"200A","ParentId":282,"Imageurl":"2024/07/20240729190435882.jpg?RTI1MOS4jeWPr+aXi+i9rOieuuafsem7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":339,"CategoryName":"150A","ParentId":282,"Imageurl":"2024/07/20240729190456384.jpg?RTEwMC0yNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":311,"CategoryName":"120A","ParentId":282,"Imageurl":"2024/07/20240729190538607.jpg?RTI1MOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":312,"CategoryName":"100A","ParentId":282,"Imageurl":"2024/07/20240729190551775.jpg?RTEwMC0yNTDkuI3lj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":313,"CategoryName":"70A","ParentId":282,"Imageurl":"2024/07/20240729190619040.jpg?RTUw5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S6buR6Imy5aWX6KOFU0tVXy5qcGc="},{"CategoryId":314,"CategoryName":"50A","ParentId":282,"Imageurl":"2024/07/20240729190633170.jpg?RTUwLTcw5LiN5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S5qmZ6Imy5aWX6KOFU0tVLmpwZw=="},{"CategoryId":1533,"CategoryName":"LP20","ParentId":298,"Imageurl":""},{"CategoryId":1526,"CategoryName":"M25B","ParentId":298,"Imageurl":""},{"CategoryId":299,"CategoryName":"P25","ParentId":298,"Imageurl":"2024/05/20240529162134233.jpg?UDIzLjIuanBn"},{"CategoryId":1531,"CategoryName":"P23","ParentId":298,"Imageurl":""},{"CategoryId":1107,"CategoryName":"P20","ParentId":298,"Imageurl":"2024/09/20240909134224415.png?UDIwLS3oiq/mlbAt5aSW57q/55u05b6E5Zu+LSA2MTN4NjEzLnBuZw=="},{"CategoryId":1530,"CategoryName":"P25X","ParentId":298,"Imageurl":""},{"CategoryId":1529,"CategoryName":"P25T","ParentId":298,"Imageurl":""},{"CategoryId":1528,"CategoryName":"P20X","ParentId":298,"Imageurl":""},{"CategoryId":1527,"CategoryName":"P20T","ParentId":298,"Imageurl":""},{"CategoryId":1165,"CategoryName":"65A","ParentId":1161,"Imageurl":"2024/07/20240729190717746.jpg?MTBtbcKy6Z2i5p2/5bel5YW36Kej6ZSB5YWs5o+S5aS0LmpwZw=="},{"CategoryId":1164,"CategoryName":"45A","ParentId":1161,"Imageurl":"2024/07/20240729190731167.jpg?Nm1twrLnur/nq6/lt6Xop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1163,"CategoryName":"35A","ParentId":1161,"Imageurl":"2024/07/20240729190743086.jpg?NG1twrLnur/nq6/lt6Xlhbfop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1201,"CategoryName":"25A","ParentId":1161,"Imageurl":"2024/07/20240729190756464.jpg?Mi41bW3Csue6v+err+W3peWFt+ino+mUgeWFrOaPkuWktC5qcGc="},{"CategoryId":1223,"CategoryName":"PG Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1243,"CategoryName":"PG Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1224,"CategoryName":"M Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1244,"CategoryName":"M Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1247,"CategoryName":"SP13","ParentId":1245,"Imageurl":""},{"CategoryId":1246,"CategoryName":"SP17","ParentId":1245,"Imageurl":""},{"CategoryId":1327,"CategoryName":"SP21","ParentId":1245,"Imageurl":""},{"CategoryId":1326,"CategoryName":"SP29","ParentId":1245,"Imageurl":""},{"CategoryId":1320,"CategoryName":"SF6","ParentId":1319,"Imageurl":""},{"CategoryId":1321,"CategoryName":"SF8","ParentId":1319,"Imageurl":""},{"CategoryId":1328,"CategoryName":"SF10","ParentId":1319,"Imageurl":""},{"CategoryId":1322,"CategoryName":"SF12","ParentId":1319,"Imageurl":""},{"CategoryId":1323,"CategoryName":"SF16","ParentId":1319,"Imageurl":""},{"CategoryId":1324,"CategoryName":"SF20","ParentId":1319,"Imageurl":""},{"CategoryId":1325,"CategoryName":"SF28","ParentId":1319,"Imageurl":""}]

Sealed For Motion: The Critical Role Of Waterproof Connectors In Advanced Robotics-Robotics Industry

The rapid evolution of the robotics industry, from automated manufacturing cells to collaborative robots and autonomous mobile platforms, is pushing the boundaries of where and how machines can operate. This expansion into dynamic, unpredictable, and often hostile environments has made connection integrity a paramount concern, not just for performance but for basic functionality. Standard electrical connections, vulnerable to minute particles, humidity, and fluids, become the weakest link in a high-value robotic system. A single failure in a sensor connection can lead to catastrophic misalignment, while corrosion in a motor power link can cause entire production lines to halt.

This is where specialized waterproof and often oil-proof connectors (typically rated IP67, IP68, and IP69K) transition from being a component to a core enabling technology. They are engineered to create flawless, hermetic seals around every electrical contact, ensuring that the critical lifeblood of a robot—power for actuators and data from vision systems, force-torque sensors, and LiDAR—flows without interruption. Whether facing routine washdowns in food processing, exposure to cutting fluids in machining, or operation in humid outdoor air, these connectors provide the resilience that allows robotics engineers to design without constraints, unlocking new applications in previously inaccessible sectors.

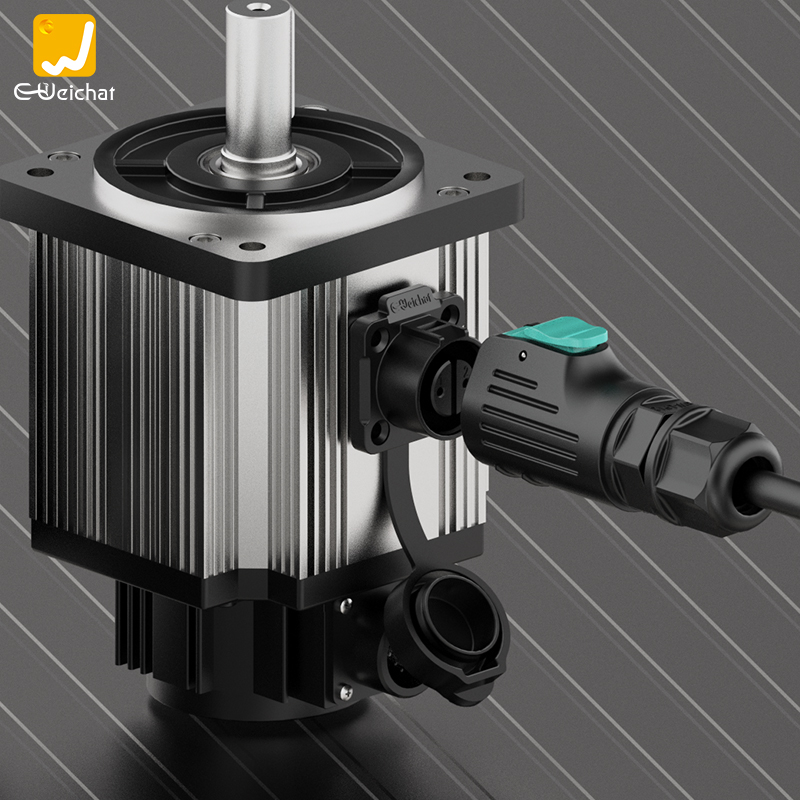

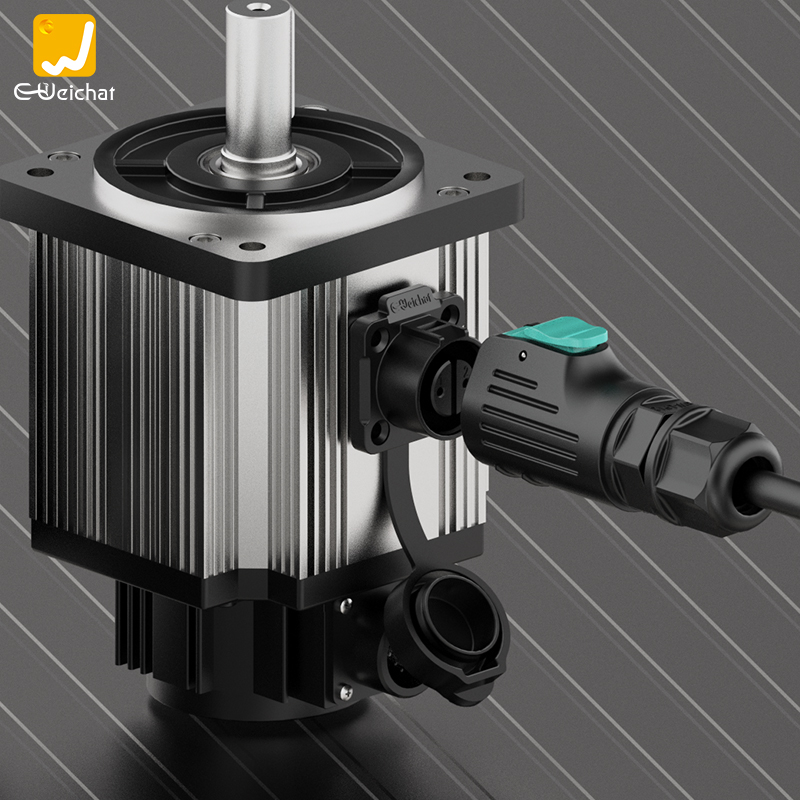

Within the anatomy of a modern industrial robot, waterproof connectors are deployed at nearly every major articulation and interface point, each with a unique set of demands. Consider a robotic arm used in automotive painting or food packaging. At its base, a large, multi-pin power and data connector links the arm to the control cabinet, requiring a robust seal against dust and splash. At each joint, where axes rotate, flexible cables run through cable tracks (cable carriers), experiencing constant flexing and torsion.

The connectors on these cables must not only be waterproof but also designed to withstand this relentless mechanical stress without compromising the seal’s integrity. Smaller, yet equally critical, M8 and M12 waterproof connectors are used to link end-of-arm tooling (EOAT), such as grippers or welders, and essential environmental sensors like 3D vision cameras. The mating mechanism is crucial here; bayonet-style or threaded couplings ensure a secure lock that vibration cannot loosen, preventing micro-leaks that would eventually lead to failure. This network of sealed connections creates a fully protected nervous system, allowing the robot to perform precise, high-speed tasks with unwavering reliability.

The implementation of a rigorous connectivity strategy using high-grade waterproof connectors delivers a powerful and compelling return on investment (ROI) that extends far beyond the initial unit cost. The most significant value is realized through dramatically increased uptime. In a 24/7 manufacturing environment, every minute of unplanned stoppage costs thousands of dollars. By eliminating connection failures caused by moisture, coolant ingress, or dust, waterproof connectors ensure continuous production, maximizing the productivity of the high-cost robotic asset.

Secondly, they drastically reduce maintenance costs and complexity. Maintenance crews are freed from the tedious, frequent task of diagnosing and replacing corroded connectors and damaged wiring harnesses. This not only saves on labor and spare parts but also enhances operational safety by reducing the need for technicians to work near potentially hazardous machinery. Furthermore, the extended lifespan of all connected components—from motors to sensors—protected by these seals adds another layer of long-term savings. The ROI is clear: investing in premium connectivity is a direct investment in predictability, productivity, and profitability.

The criticality of waterproof connectors becomes even more apparent when examining robotics applications at the extremes of operational environments. In agricultural robotics, autonomous weeders and harvesters operate in fields with high humidity, dust, and mud. Connectors must resist not just moisture but also chemical exposure from fertilizers and pesticides. In food and beverage automation, robots must endure daily high-pressure, high-temperature washdowns with harsh cleaning chemicals and sanitizing agents. Here, connectors with IP69K ratings and stainless steel housings are mandatory to meet hygiene standards and prevent failure.

For underwater robotics (ROVs) used in marine research, offshore energy, and aquaculture, connectors must withstand immense pressure while maintaining a perfect seal, often requiring specialized radial sealing technology and pressure compensation. Even in cleanroom settings for electronics or pharmaceutical manufacturing, where absolute control over particulate contamination is required, connectors must be sealed to prevent any internal outgassing or particle generation. Each of these challenging scenarios demands a meticulously specified connector solution, highlighting its role as the guardian of performance in the face of adversity.

For robotics integrators and OEMs, selecting the right waterproof connector is a strategic engineering decision that requires a systematic, multi-faceted evaluation. The process begins with a thorough assessment of the environmental stressors: the type of fluid (water, oil, coolant, chemicals), pressure levels, temperature cycles, and the presence of abrasives or vibration. This determines the required IP rating and material selection, such as opting for chemical-resistant seals like FKM (Viton) over standard NBR rubber for aggressive washdowns.

The mechanical requirements are equally critical: the connector must be compatible with continuous flexing if used in a cable carrier, necessitating a design with strain relief and flexible cable. The electrical specifications—number of contacts, current rating, and need for mixed power/signal/data transmission (e.g., hybrid connectors)—must support both immediate needs and future scalability. Finally, the human factor cannot be ignored; the connector should feature an ergonomic mating mechanism that provides audible or tactile confirmation of a secure connection, enabling faster assembly and maintenance in the field. Partnering with a connector manufacturer that offers extensive customization, global technical support, and a proven track record in robotics is essential for building systems that are not only intelligent and powerful but also supremely reliable and built to last.

-

Fast and Convenient

-

Customization

- Need a technical consultant to answer your questions?

-

-

Hot Promoted Products

Recommend current hot products to you