[{"CategoryId":271,"CategoryName":"By Series","ParentId":0,"Imageurl":""},{"CategoryId":272,"CategoryName":"By Size","ParentId":0,"Imageurl":""},{"CategoryId":273,"CategoryName":"By Number of Pins","ParentId":0,"Imageurl":""},{"CategoryId":274,"CategoryName":"By Application","ParentId":0,"Imageurl":""},{"CategoryId":275,"CategoryName":"By Wiring","ParentId":0,"Imageurl":""},{"CategoryId":276,"CategoryName":"Customization","ParentId":0,"Imageurl":""},{"CategoryId":277,"CategoryName":"By Material","ParentId":0,"Imageurl":""},{"CategoryId":278,"CategoryName":"LP Series","ParentId":271,"Imageurl":"2025/07/20250724101928371.jpg?TFDns7vliJcuYmlwLjI1NTUuanBn"},{"CategoryId":1319,"CategoryName":"SF Series","ParentId":271,"Imageurl":"2025/09/20250913181601452.jpg?U0Y2LTgtMTDlhajlrrbnpo8uanBn"},{"CategoryId":1245,"CategoryName":"SP Series","ParentId":271,"Imageurl":"2025/09/20250913181428839.jpg?U1AuanBn"},{"CategoryId":279,"CategoryName":"Self Locking Series","ParentId":271,"Imageurl":"2024/09/20240905134920982.png?U2VsZiBMb2NraW5nIFNlcmllcw=="},{"CategoryId":280,"CategoryName":"Waterproof Cable Connector","ParentId":271,"Imageurl":"2024/09/20240905142754587.png?V2F0ZXJwcm9vZiBDYWJsZSBDb25uZWN0b3I="},{"CategoryId":281,"CategoryName":"Junction Box","ParentId":271,"Imageurl":"2024/09/20240905155939966.png?5o6l57q/55uS57O75YiXIDYxM3g2MTMucG5n"},{"CategoryId":1222,"CategoryName":"Cable Gland","ParentId":271,"Imageurl":"2025/03/20250320135315907.jpg?Y2FibGUtZ2xhbmQuanBn"},{"CategoryId":282,"CategoryName":"Energy Storage Connector","ParentId":271,"Imageurl":"2024/09/20240905143234262.png?RW5lcmd5IFN0b3JhZ2UgQ29ubmVjdG9y"},{"CategoryId":1161,"CategoryName":"PV Connector","ParentId":271,"Imageurl":"2024/09/20240905143119031.png?UFYgQ29ubmVjdG9y"},{"CategoryId":1351,"CategoryName":"M29","ParentId":272,"Imageurl":""},{"CategoryId":1170,"CategoryName":"M28","ParentId":272,"Imageurl":"2024/12/20241204113448729.png?TTI4IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1169,"CategoryName":"M25","ParentId":272,"Imageurl":"2024/12/20241204113352959.png?TTI1IGNpcmN1bGFyIHBsYXN0aWMgd2lyZSBjb25uZWN0b3I="},{"CategoryId":319,"CategoryName":"M24","ParentId":272,"Imageurl":"2024/12/20241204113237802.png?TTI0IEluZHVzdHJpYWwgd2F0ZXJwcm9vZiBjb25uZWN0b3I="},{"CategoryId":1168,"CategoryName":"M23","ParentId":272,"Imageurl":"2024/12/20241204112141563.png?TTIzIHdhdGVycHJvb2YgcGx1ZyBjb25uZWN0b3Jz"},{"CategoryId":1350,"CategoryName":"M21","ParentId":272,"Imageurl":""},{"CategoryId":318,"CategoryName":"M20","ParentId":272,"Imageurl":"2024/12/20241204112034702.png?TTIwIGNpcmN1bGFyIGNvbm5lY3Rvcg=="},{"CategoryId":1167,"CategoryName":"M19","ParentId":272,"Imageurl":"2024/12/20241204111937164.png?TTE5IHdhdGVycHJvb2Ygd2lyZSBjb25uZWN0b3Jz"},{"CategoryId":1349,"CategoryName":"M17","ParentId":272,"Imageurl":""},{"CategoryId":293,"CategoryName":"M16","ParentId":272,"Imageurl":"2024/12/20241204111827969.png?TTE2IGVsZWN0cmljYWwgY29ubmVjdG9y"},{"CategoryId":1166,"CategoryName":"M15","ParentId":272,"Imageurl":"2024/12/20241204111717740.png?TTE1IG1hbGUgYW5kIGZlbWFsZSBjb25uZWN0b3Jz"},{"CategoryId":1348,"CategoryName":"M13","ParentId":272,"Imageurl":""},{"CategoryId":292,"CategoryName":"M12","ParentId":272,"Imageurl":"2024/12/20241204111548642.png?TTEyIFdhdGVycHJvb2YgTTEyIENvbm5lY3Rvcg=="},{"CategoryId":1347,"CategoryName":"M10","ParentId":272,"Imageurl":""},{"CategoryId":1346,"CategoryName":"M8","ParentId":272,"Imageurl":""},{"CategoryId":1345,"CategoryName":"M6","ParentId":272,"Imageurl":""},{"CategoryId":335,"CategoryName":"TYPE-C","ParentId":273,"Imageurl":"2024/08/20240803175816209.jpg?TFAxNi1UWVBFLUPph5HlsZ7ms5XlhbAuanBn"},{"CategoryId":334,"CategoryName":"Fiber","ParentId":273,"Imageurl":"2024/07/20240730100446602.png?TFAyNC1GSUJFUig2KSAyMDB4MjAwIC0g5Ymv5pysLnBuZw=="},{"CategoryId":333,"CategoryName":"HDMI","ParentId":273,"Imageurl":"2024/07/20240730100616849.png?TFAyNC1IRE1JKDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":332,"CategoryName":"USB","ParentId":273,"Imageurl":"2024/07/20240730100646405.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":331,"CategoryName":"RJ45","ParentId":273,"Imageurl":"2024/07/20240730100713409.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlr7nmjqUucG5n"},{"CategoryId":1335,"CategoryName":"26 Pins","ParentId":273,"Imageurl":"2025/09/20250908170725350.jpg?U1AyOS0yNlDkuKTlrZTluqfmraPoo4UgODAweDgwMC5qcGc="},{"CategoryId":330,"CategoryName":"24 Pins","ParentId":273,"Imageurl":"2024/07/20240730101220115.jpg?TFAyNC0yNFDpnaLmnb/ph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1334,"CategoryName":"20 Pins","ParentId":273,"Imageurl":"2025/09/20250908170702461.jpg?U0YyOC0yMFDpnaLmnb8gODAweDgwMC5qcGc="},{"CategoryId":329,"CategoryName":"19 Pins","ParentId":273,"Imageurl":"2024/07/20240730101243254.jpg?TFAyNC0xOVDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":1333,"CategoryName":"18 Pins","ParentId":273,"Imageurl":"2025/09/20250908170641433.jpg?U0YyOC0xOFDlr7nmjqUgODAweDgwMC5qcGc="},{"CategoryId":1344,"CategoryName":"17 Pins","ParentId":273,"Imageurl":""},{"CategoryId":1332,"CategoryName":"16 Pins","ParentId":273,"Imageurl":"2025/09/20250908170620266.jpg?U0YyOC0xNlDpnaLmnb/luqflj43oo4UgODAweDgwMC5qcGc="},{"CategoryId":1215,"CategoryName":"14 Pins","ParentId":273,"Imageurl":"2024/08/20240808120100973.jpg?TFAyMC0xNFDms5XlhbDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":328,"CategoryName":"12 Pins","ParentId":273,"Imageurl":"2024/07/20240730101400996.png?TFAyNC0xMlDms5XlhbDloZHmlpnlj43oo4XmrL4ucG5n"},{"CategoryId":327,"CategoryName":"10 Pins","ParentId":273,"Imageurl":"2024/07/20240730101422023.jpg?TFAyNC0xMFDlr7nmj5Lph5HlsZ7lj43oo4XmrL4uanBn"},{"CategoryId":326,"CategoryName":"9 Pins","ParentId":273,"Imageurl":"2024/07/20240730101545901.jpg?TFAyMC05UC3lr7nmj5ItMy5qcGc="},{"CategoryId":325,"CategoryName":"8 Pins","ParentId":273,"Imageurl":"2024/07/20240730101729864.jpg?TFAxNi04UOmdouadv0zph5HlsZ7mraPoo4UuanBn"},{"CategoryId":324,"CategoryName":"7 Pins","ParentId":273,"Imageurl":"2024/07/20240730101805407.jpg?TFAxNi03UOazleWFsFDph5HlsZ7mraPoo4UuanBn"},{"CategoryId":323,"CategoryName":"6 Pins","ParentId":273,"Imageurl":"2024/07/20240730101848277.png?TFAxMi02UCDlj43oo4UgMi5wbmc="},{"CategoryId":322,"CategoryName":"5 Pins","ParentId":273,"Imageurl":"2024/07/20240730102001465.jpg?TFAyNC01UOWFrOaPklPph5HlsZ7lj43oo4XplIHnur/mrL4uanBn"},{"CategoryId":321,"CategoryName":"4 Pins","ParentId":273,"Imageurl":"2024/07/20240730102053511.png?TFAyMC00UOazleWFsOWhkeaWmeato+ijhS5wbmc="},{"CategoryId":320,"CategoryName":"3 Pins","ParentId":273,"Imageurl":"2024/07/20240730102122414.jpg?TFAyOC0zUOWvueaPkuWhkeaWmeato+ijhS5qcGc="},{"CategoryId":295,"CategoryName":"2 Pins","ParentId":273,"Imageurl":"2024/07/20240730102152158.jpg?TFAyOC0yUOazleWFsOWhkeaWmeato+ijhS5qcGc="},{"CategoryId":294,"CategoryName":"1 Pin","ParentId":273,"Imageurl":"2024/12/20241202141836844.png?ZW5lcmd5IHN0b3JhZ2UgY29ubmVjdG9y"},{"CategoryId":315,"CategoryName":"Signal Connector","ParentId":274,"Imageurl":"2024/07/20240730133750759.png?TFAyNC1SSjQ1KDYpIDIwMHgyMDAgLSDlia/mnKwucG5n"},{"CategoryId":297,"CategoryName":"Data Connector","ParentId":274,"Imageurl":"2024/07/20240730093457270.png?TFAyNC1VU0IoNikgMjAweDIwMCAtIOWJr+acrC5wbmc="},{"CategoryId":296,"CategoryName":"Power Connector","ParentId":274,"Imageurl":"2024/08/20240803175721975.jpg?TFAxNi00UCg5KS5qcGc="},{"CategoryId":338,"CategoryName":"Crimping Type","ParentId":275,"Imageurl":"2024/12/20241202143025954.png?TFAxMi0yUOWvueaPkumHkeWxnuato+ijhSA3NTB4NzUwLnBuZw=="},{"CategoryId":336,"CategoryName":"Solder Type","ParentId":275,"Imageurl":"2024/12/20241202142826795.png?TFAyNC0y6Iqv54SK5o6l5aGR5paZ5qy+5rOV5YWw5Y+N6KOFc2t1LnBuZw=="},{"CategoryId":337,"CategoryName":"Screw Type","ParentId":275,"Imageurl":"2024/12/20241202142506193.png?TFAxMi0yUOazleWFsFDph5HlsZ7plIHnur/lj43oo4UucG5n"},{"CategoryId":298,"CategoryName":"Screwless Type","ParentId":275,"Imageurl":"2024/05/20240529162027688.jpg?5b+r5o6l57O75YiXLmpwZw=="},{"CategoryId":301,"CategoryName":"Mix Pins","ParentId":276,"Imageurl":"2024/07/20240730102324120.jpg?TFAyOC0zUOazleWFsOWhkeaWmeato+ijhS0xLmpwZw=="},{"CategoryId":1330,"CategoryName":"Color","ParentId":276,"Imageurl":""},{"CategoryId":317,"CategoryName":"Metal + Plastic","ParentId":277,"Imageurl":"2024/08/20240803180032739.jpg?TFAxMi00UOazleWFsOmHkeWxnuWPjeijhS5qcGc="},{"CategoryId":316,"CategoryName":"All Metal","ParentId":277,"Imageurl":"2024/11/20241121135153910.png?TFAxMi0yUOazleWFsOasvumUgee6vy5wbmc="},{"CategoryId":300,"CategoryName":"All Plastic","ParentId":277,"Imageurl":"2024/08/20240803180224853.png?TFAxMi00UCDlj43oo4UgNy5wbmc="},{"CategoryId":287,"CategoryName":"LP12","ParentId":278,"Imageurl":"2024/12/20241203141919861.png?TFAxMiBlbGVjdHJpY2FsIHdhdGVycHJvb2YgY29ubmVjdG9ycw=="},{"CategoryId":283,"CategoryName":"LP16","ParentId":278,"Imageurl":"2024/12/20241203141926793.png?TFAxNiB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":286,"CategoryName":"LP20","ParentId":278,"Imageurl":"2024/12/20241203140522654.png?TFAyMCBJbmR1c3RyaWFsIHdhdGVycHJvb2YgY29ubmVjdG9y"},{"CategoryId":285,"CategoryName":"LP24","ParentId":278,"Imageurl":"2024/12/20241203140638274.jpg?TFAyNCB3YXRlcnByb29mIHBsdWcgY29ubmVjdG9ycw=="},{"CategoryId":284,"CategoryName":"LP28","ParentId":278,"Imageurl":"2024/12/20241203140831377.png?TFAyOCBXYXRlcnByb29mIENhYmxlIENvbm5lY3Rvcg=="},{"CategoryId":303,"CategoryName":"M15MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095659595.jpg?TTE1TUYtM1AuanBn"},{"CategoryId":304,"CategoryName":"M19MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095626837.jpg?6Z2i5p2/55m95bqVIC0g5Ymv5pysLmpwZw=="},{"CategoryId":305,"CategoryName":"M23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095548936.jpg?RVctTTIzTVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":307,"CategoryName":"M28MP/MF","ParentId":279,"Imageurl":"2024/07/20240730095408770.jpg?RVctTTI4TVDpnaLmnb/mrL7kuLvlm74uanBn"},{"CategoryId":306,"CategoryName":"P25MP/MF","ParentId":279,"Imageurl":"2024/07/20240729185729105.png?UDI1LS3oiq/mlbAt5aSW57q/55u05b6E5Zu+IDIwMHgyMDAucG5n"},{"CategoryId":1209,"CategoryName":"P23MP/MF","ParentId":279,"Imageurl":"2024/07/20240730100244127.png?UDIzLnBuZw=="},{"CategoryId":302,"CategoryName":"Screw Connector Series","ParentId":280,"Imageurl":"2024/12/20241203142740551.png?U2NyZXcgQ29ubmVjdG9yIFNlcmllcw=="},{"CategoryId":289,"CategoryName":"Screwless Connector Series","ParentId":280,"Imageurl":"2024/09/20240905144436844.png?U2NyZXdsZXNzIENvbm5lY3RvciBTZXJpZXM="},{"CategoryId":1536,"CategoryName":"2068N Serie","ParentId":281,"Imageurl":"2026/01/20260116110540406.png?TTIwNjhOLTJUICAoMikucG5n"},{"CategoryId":290,"CategoryName":"2068 Serie","ParentId":281,"Imageurl":"2024/07/20240730094848584.png?RVctTTIwNjgtNVQucG5n"},{"CategoryId":308,"CategoryName":"2068S Serie","ParentId":281,"Imageurl":"2024/07/20240729190104148.jpg?55m95bqVMy5qcGc="},{"CategoryId":309,"CategoryName":"2068L Serie","ParentId":281,"Imageurl":"2024/07/20240729190043564.jpg?55m95bqVMi5qcGc="},{"CategoryId":310,"CategoryName":"2068XL Serie","ParentId":281,"Imageurl":"2024/07/20240730094724530.jpg?MTAuanBn"},{"CategoryId":1159,"CategoryName":"350A","ParentId":282,"Imageurl":"2024/07/20240729190329212.jpg?RTMwMC0zNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":1158,"CategoryName":"300A","ParentId":282,"Imageurl":"2024/07/20240729190349998.jpg?RTMwMOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":341,"CategoryName":"250A","ParentId":282,"Imageurl":"2024/07/20240729190408955.jpg?RTEwMC0yNTDlj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":340,"CategoryName":"200A","ParentId":282,"Imageurl":"2024/07/20240729190435882.jpg?RTI1MOS4jeWPr+aXi+i9rOieuuafsem7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":339,"CategoryName":"150A","ParentId":282,"Imageurl":"2024/07/20240729190456384.jpg?RTEwMC0yNTDlj6/ml4vovazlhYnlrZTpk5zmjpLmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":311,"CategoryName":"120A","ParentId":282,"Imageurl":"2024/07/20240729190538607.jpg?RTI1MOS4jeWPr+aXi+i9rOWFieWtlOmTnOaOkum7keiJsuWll+ijhVNLVS5qcGc="},{"CategoryId":312,"CategoryName":"100A","ParentId":282,"Imageurl":"2024/07/20240729190551775.jpg?RTEwMC0yNTDkuI3lj6/ml4vovazonrrmn7HmqZnoibLlpZfoo4VTS1UuanBn"},{"CategoryId":313,"CategoryName":"70A","ParentId":282,"Imageurl":"2024/07/20240729190619040.jpg?RTUw5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S6buR6Imy5aWX6KOFU0tVXy5qcGc="},{"CategoryId":314,"CategoryName":"50A","ParentId":282,"Imageurl":"2024/07/20240729190633170.jpg?RTUwLTcw5LiN5Y+v5peL6L2s5YWJ5a2U6ZOc5o6S5qmZ6Imy5aWX6KOFU0tVLmpwZw=="},{"CategoryId":1533,"CategoryName":"LP20","ParentId":298,"Imageurl":""},{"CategoryId":1526,"CategoryName":"M25B","ParentId":298,"Imageurl":""},{"CategoryId":299,"CategoryName":"P25","ParentId":298,"Imageurl":"2024/05/20240529162134233.jpg?UDIzLjIuanBn"},{"CategoryId":1531,"CategoryName":"P23","ParentId":298,"Imageurl":""},{"CategoryId":1107,"CategoryName":"P20","ParentId":298,"Imageurl":"2024/09/20240909134224415.png?UDIwLS3oiq/mlbAt5aSW57q/55u05b6E5Zu+LSA2MTN4NjEzLnBuZw=="},{"CategoryId":1530,"CategoryName":"P25X","ParentId":298,"Imageurl":""},{"CategoryId":1529,"CategoryName":"P25T","ParentId":298,"Imageurl":""},{"CategoryId":1528,"CategoryName":"P20X","ParentId":298,"Imageurl":""},{"CategoryId":1527,"CategoryName":"P20T","ParentId":298,"Imageurl":""},{"CategoryId":1165,"CategoryName":"65A","ParentId":1161,"Imageurl":"2024/07/20240729190717746.jpg?MTBtbcKy6Z2i5p2/5bel5YW36Kej6ZSB5YWs5o+S5aS0LmpwZw=="},{"CategoryId":1164,"CategoryName":"45A","ParentId":1161,"Imageurl":"2024/07/20240729190731167.jpg?Nm1twrLnur/nq6/lt6Xop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1163,"CategoryName":"35A","ParentId":1161,"Imageurl":"2024/07/20240729190743086.jpg?NG1twrLnur/nq6/lt6Xlhbfop6PplIHlhazmj5LlpLQuanBn"},{"CategoryId":1201,"CategoryName":"25A","ParentId":1161,"Imageurl":"2024/07/20240729190756464.jpg?Mi41bW3Csue6v+err+W3peWFt+ino+mUgeWFrOaPkuWktC5qcGc="},{"CategoryId":1223,"CategoryName":"PG Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1243,"CategoryName":"PG Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1224,"CategoryName":"M Metal Series","ParentId":1222,"Imageurl":""},{"CategoryId":1244,"CategoryName":"M Plastic Series","ParentId":1222,"Imageurl":""},{"CategoryId":1247,"CategoryName":"SP13","ParentId":1245,"Imageurl":""},{"CategoryId":1246,"CategoryName":"SP17","ParentId":1245,"Imageurl":""},{"CategoryId":1327,"CategoryName":"SP21","ParentId":1245,"Imageurl":""},{"CategoryId":1326,"CategoryName":"SP29","ParentId":1245,"Imageurl":""},{"CategoryId":1320,"CategoryName":"SF6","ParentId":1319,"Imageurl":""},{"CategoryId":1321,"CategoryName":"SF8","ParentId":1319,"Imageurl":""},{"CategoryId":1328,"CategoryName":"SF10","ParentId":1319,"Imageurl":""},{"CategoryId":1322,"CategoryName":"SF12","ParentId":1319,"Imageurl":""},{"CategoryId":1323,"CategoryName":"SF16","ParentId":1319,"Imageurl":""},{"CategoryId":1324,"CategoryName":"SF20","ParentId":1319,"Imageurl":""},{"CategoryId":1325,"CategoryName":"SF28","ParentId":1319,"Imageurl":""}]

Waterproof Connectors Are A Fundamental Aspect Of Designing Robust Tunnel Lighting Systems-医疗行业新能源行业通讯行业工控设备机器人行业照明行业产品知识媒体报道公司新闻常见问题答疑产品基础知识连接器选型产品证书宣传资料安装视频安装流程书三维图产品规格书防水接线端子储能连接器防水接线盒数据连接器电源连接器信号连接器Waterproof Cable ConnectorEnergy Storage ConnectorJunction BoxData ConnectorSignal ConnectorPower ConnectorMedical IndustryNew Energy IndustryCommunications IndustryIndustrial Control EquipmentRobotics IndustryLighting IndustryFAQProduct BasicsConnector SelectionProduct CertificatePropagandaInstallation VideoInstallation Procedure BookThree Dimensional MapProduct SpecificationsProduct KnowledgeMediaCompany NewsPV ConnectorCable GlandLighting Connector

In today's rapidly advancing technological landscape, the reliability and durability of electrical connections are paramount, particularly in challenging environments. Waterproof connectors have emerged as essential components in various applications, ensuring that electrical systems function effectively even in adverse conditions. These specialized connectors are designed to withstand exposure to moisture, dust, and extreme temperatures, thus enhancing the longevity and performance of electronic systems.

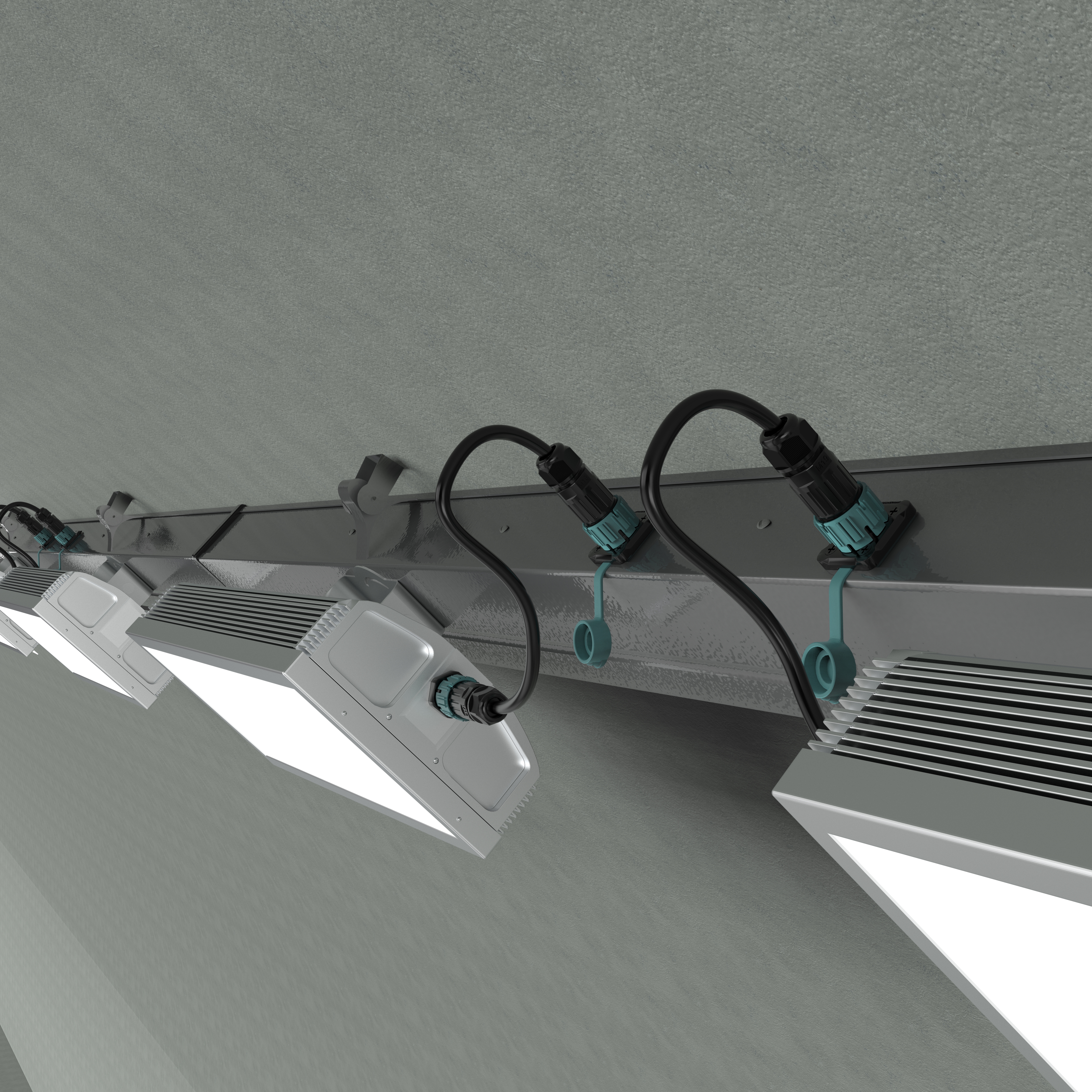

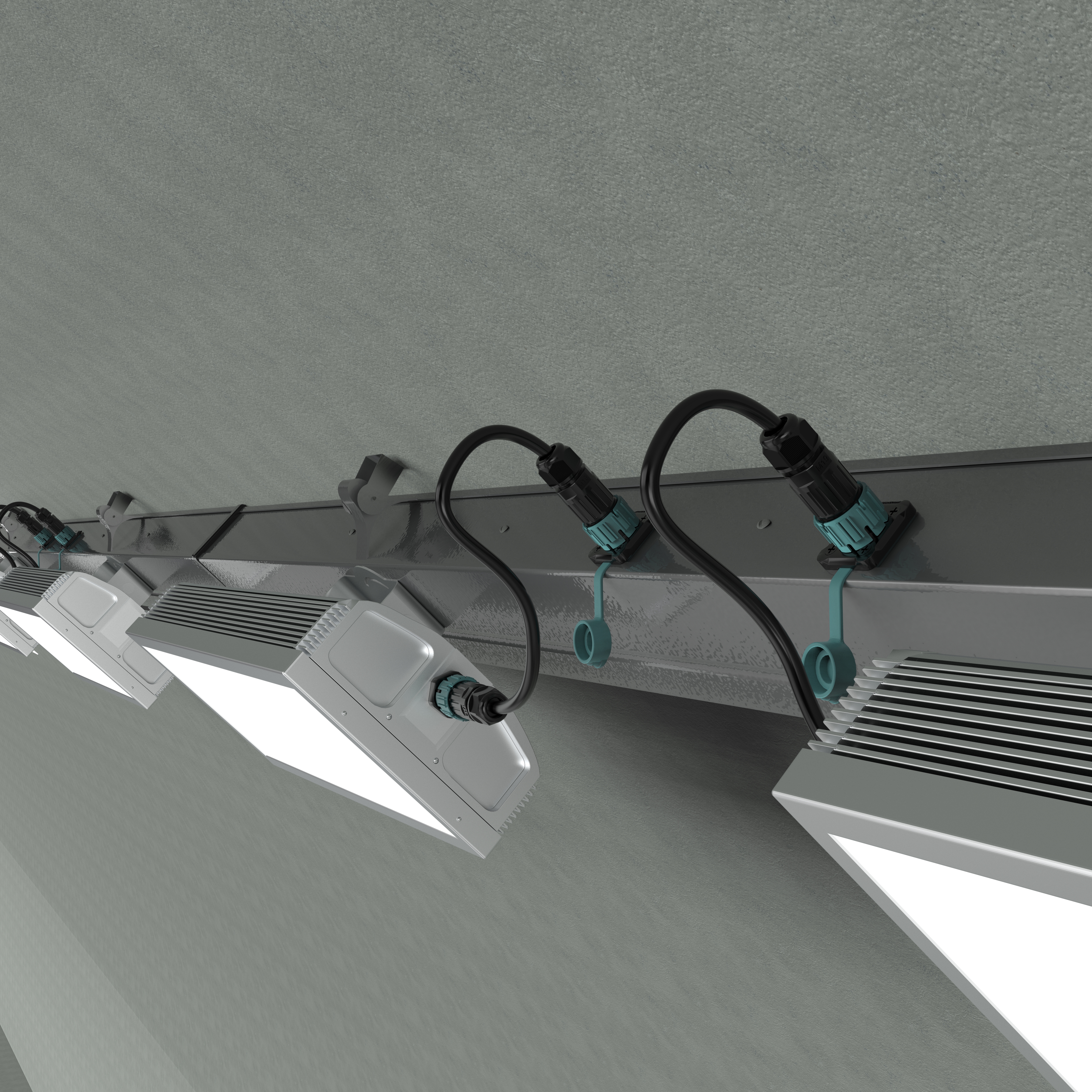

Tunnels present unique challenges due to their enclosed nature and the high likelihood of water infiltration, which can lead to electrical failures if inadequate protective measures are implemented. As a result, the integration of waterproof connectors is not merely a technical requirement but a fundamental aspect of designing robust tunnel lighting systems.

This document will provide an overview of the various applications of waterproof connectors, with a particular focus on tunnel lighting. We will delve into the specifics of tunnel lighting systems, the environmental challenges they face, and how waterproof connectors play a crucial role in ensuring their reliability. In doing so, we aim to underscore the growing relevance of these components in modern engineering and infrastructure development.

In applications like tunnel lighting, the presence of water, dust, and varying temperatures can have detrimental effects on electrical connections. These adverse conditions can lead to corrosion, electrical shorts, and equipment failure, resulting in increased maintenance costs and safety hazards.

The use of waterproof connectors mitigates these risks by providing a secure and protective interface for electrical connections. These connectors are designed to prevent moisture ingress, thereby preserving the integrity of the electrical systems in high-humidity environments such as tunnels. By ensuring reliable performance, waterproof connectors contribute to the longevity of lighting systems and reduce downtime caused by maintenance and repairs.

Underwater Measuring Probes

Introduction to Underwater Measuring Probes

Underwater measuring probes are essential tools used in various applications such as environmental monitoring, research, and industrial processes. These probes are designed to operate in submerged conditions, providing accurate data about parameters such as temperature, pressure, and water quality. Given their operational environment, the effectiveness of these probes heavily relies on their ability to withstand water intrusion and maintain functionality.

Requirements for Waterproofing

The primary requirement for underwater measuring probes is robust waterproofing. This is critical not only to ensure the longevity of the probes but also to guarantee accurate readings. Waterproofing must comply with specific industry standards (such as IP68) to withstand prolonged exposure to water, including conditions encountered in deep or turbulent environments. It is crucial that seals and materials used in the construction of the probes are chosen carefully to prevent any ingress of water or corrosive substances.

Implementation of Waterproof Connectors

Waterproof connectors play a pivotal role in the functionality of underwater measuring probes. These connectors must be designed to ensure a secure and reliable connection between the probes and their respective data transmission systems. By utilizing high-quality waterproof connectors, manufacturers can ensure that electrical connections remain safe and operational even under extreme pressure and submersion conditions. Effective implementation of these connectors minimizes maintenance needs and enhances the overall reliability of underwater measuring systems, thereby ensuring accurate data collection over extended periods.

Integration of Waterproof Connectors

The integration of waterproof connectors in submersible pumps is crucial for ensuring reliable operation in harsh environmental conditions. Submersible pumps are designed to operate underwater, often in challenging scenarios such as sewage systems, water treatment facilities, and deep wells. The connectors used in these applications must meet stringent requirements to withstand not only water pressure but also potential contaminants that could compromise their functionality.

To achieve this, waterproof connectors are selected based on several key criteria, including ingress protection (IP) ratings, material compatibility, and durability. High IP ratings, such as IP68, indicate that the connectors can resist dust and can be submerged in water for extended periods without failure. Materials such as thermoplastic elastomers and corrosion-resistant metals are often used to enhance the longevity and performance of the connectors.

The implementation process involves careful planning and design to ensure that the connectors are positioned to minimize exposure to physical stress and potential damage. Proper sealing techniques, such as the use of O-rings and gaskets, are also employed to create watertight connections that prevent leaks. Additionally, the connectors must be easily accessible for maintenance and replacement, enabling efficient operation of the submersible pumps.

By effectively integrating waterproof connectors into submersible pump systems, operators can enhance the reliability and safety of their installations, ensuring continuous performance in demanding underwater environments.

Summary of Applications

Among these applications, tunnel lighting systems serve as a primary example, highlighting the importance of reliable electrical connections in underground environments. Tunnel lighting systems require robust connectors that resist water ingress and ensure consistent illumination for safety and operational efficiency.

In addition to tunnel lighting, underwater measuring probes represent another critical application of waterproof connectors. These devices are essential for environmental monitoring and require connectors that can withstand prolonged submersion while maintaining signal integrity. The demands for waterproofing in these probes are stringent, necessitating advanced materials and design techniques.

Submersible pumps also require careful consideration in terms of waterproof connectivity. The supply lines for these pumps must be equipped with connectors that endure varying pressure levels and environmental conditions without compromising functionality. Integrating waterproof connectors into these systems is essential for preventing downtime and ensuring the reliable operation of vital infrastructure.

In conclusion, the applications of waterproof connectors extend beyond tunnel lighting to include underwater measuring probes and submersible pumps. Each application presents unique challenges that highlight the necessity of employing high-quality waterproof connectors. As technology advances, the demand for innovative waterproof solutions is expected to grow, driving future trends in this critical area of electrical engineering.

-

Fast and Convenient

-

Customization

- Need a technical consultant to answer your questions?

-

-

Hot Promoted Products

Recommend current hot products to you